Modular oxygen generator

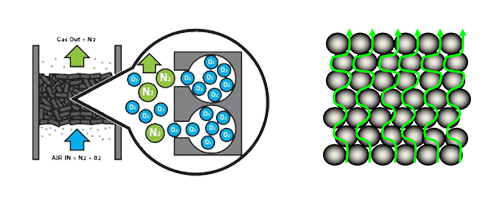

The principle of pressure swing adsorption oxygen making is similar to the principle of pressure swing adsorption nitrogen making, but it will use a different adsorbent from the nitrogen making process --- ZMS (Zeolite Molecular Sieve), which also uses clean compressed air as raw material. Under pressure conditions, nitrogen is adsorbed by the zeolite molecular sieve, only a small amount of oxygen is adsorbed, and the unadsorbed oxygen is output as product gas. When the adsorbent reaches saturation, nitrogen can be desorbed from the molecular sieve by means of a pressure reduction process, and the adsorbent is regenerated. The use of multiple adsorption beds for cyclic operation can achieve the purpose of continuous oxygen producing. The highest flow rate can reach the highest purity, which can reach 93±2%. The flow rate is related to the purity and can be customized according to the customer's application requirements.Principle description of pressure swing adsorption (PSA):

Take modular nitrogen generator as an example to do the following description. The principle is to select Pressure Swing Adsorption (PSA) as shown in the figure below. Clean air is used as raw material and high-quality carbon molecular sieve is used as raw material. The adsorbent, under a certain pressure, pressurized adsorption, reduced pressure desorption, and the adsorbers work alternately to obtain nitrogen with the required purity. At the same time, it absorbs the advantages of membrane separation products, and its excellent nitrogen quality and plug-and-play convenience make it easier to be accepted by customers.Product features:

1. High reliability:time-tested technology; high-end system configuration to ensure long-term stable operation; optimized design to ensure excellent nitrogen quality.2. Fast and convenient: optimized structure, compact design; convenient to connect to existing compressed air; plug and play.

3. Cost saving: 7x24h uninterrupted supply; low operating cost; no safety hazards such as high-pressure gas cylinders and low-temperature liquid nitrogen storage tanks.

4. Scalability: Standard adsorber, modular design, occupying a smaller area; it can be expanded on demand, only need to add CMS module; multiple units can be connected in parallel for easy expansion.

Application industries:

1) Aquatic fish farming

2) Sewage and wastewater treatment

3) Welding, cutting and brazing

4) Glass blowing and lighting

1) Aquatic fish farming

2) Sewage and wastewater treatment

3) Welding, cutting and brazing

4) Glass blowing and lighting