Application of nitrogen generator in biomedicine field

发布时间:2024-01-11 浏览次数:922

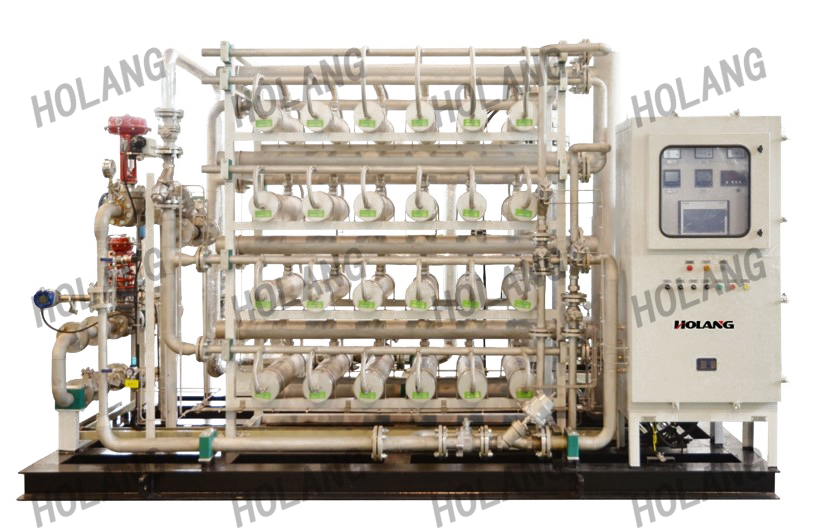

Nitrogen generators have wide applications in the biopharmaceutical industry. They are used in various processes where high-quality nitrogen is required. The basic principle of a nitrogen generator is to separate nitrogen from air using physical or chemical methods. The most common methods are Pressure Swing Adsorption (PSA) and membrane separation.

In the biopharmaceutical industry, nitrogen generators play a crucial role in several applications:

Drug manufacturing:Nitrogen is used as an inert atmosphere to prevent oxidation reactions when manufacturing drugs. It also protects sensitive drug components from contamination by oxygen and moisture.

Drug packaging and preservation:Nitrogen is commonly used for packaging and preserving pharmaceutical products. Many drugs need to be protected from oxygen exposure during preparation to prevent oxidation or degradation. Nitrogen generators provide an inert atmosphere, eliminating oxygen from the packaging container and maintaining the stability, effectiveness, and shelf life of the drugs. This is particularly important for biologics, oxygen-sensitive drugs, and sterilized products.

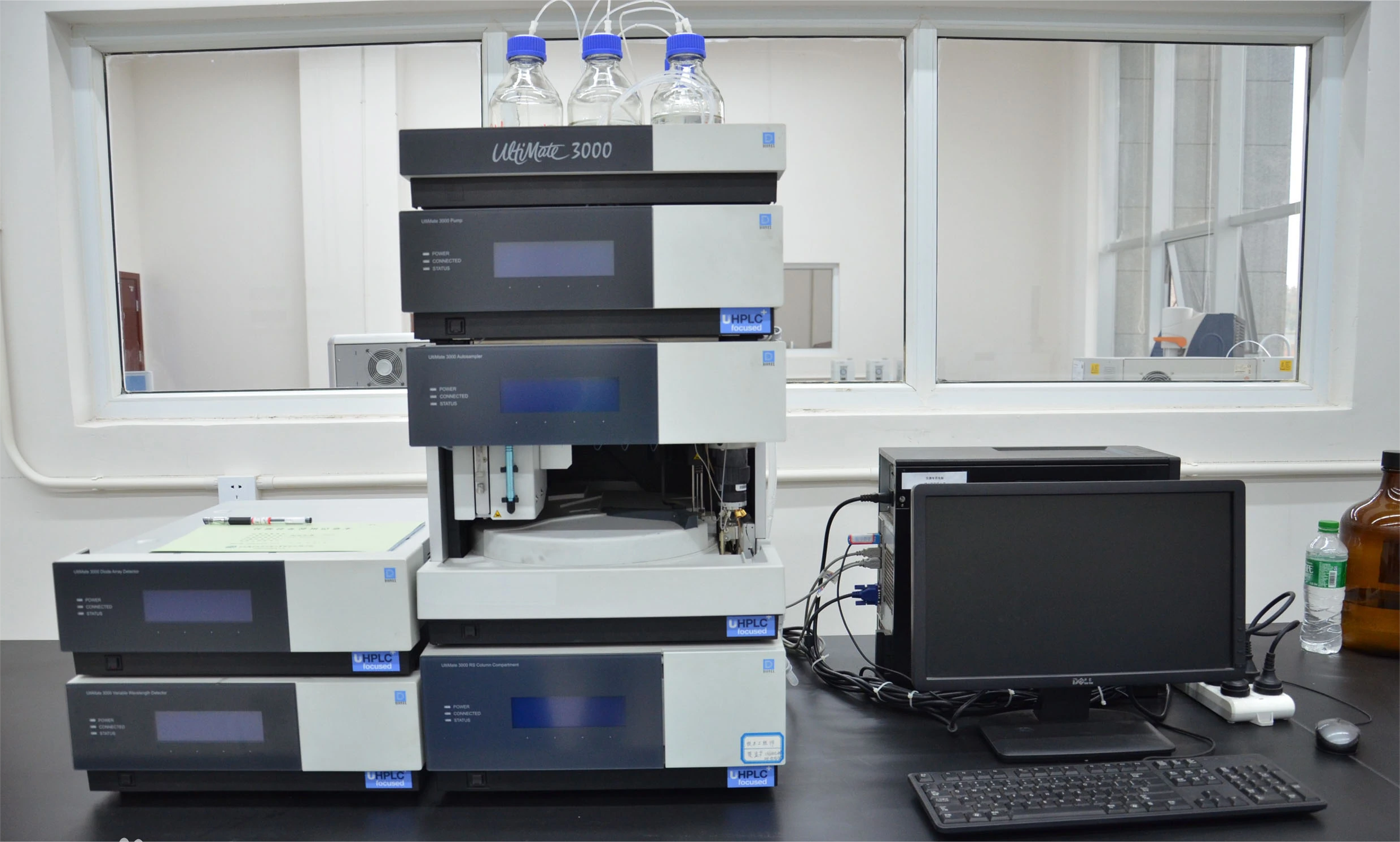

Research and experiments: Pure nitrogen is required in laboratories as a carrier or protective gas to ensure accurate and reproducible results. Nitrogen generators provide high-purity nitrogen to meet the laboratory's needs. They are also used in various stages of drug development, such as synthesis reactions, drying, and storage, providing optimal experimental conditions and production support. Additionally, nitrogen generators are used for the operation of instruments like gas chromatographs and mass spectrometers.

Medical equipment: Nitrogen generators find common applications in medical devices. They are used for drying and cleaning during the manufacturing process of medical equipment. In medical gas supply systems, nitrogen generators provide a stable source of nitrogen for anesthesia machines, ventilators, and other devices.

Moreover, nitrogen is used for anesthesia and hemostasis in surgical procedures, anesthesia and root canal therapy in dental treatments, cryotherapy and acne treatment in dermatology, among other medical applications.

When selecting a nitrogen generator for pharmaceutical applications, factors such as purity requirements, flow rate demands, stability, and reliability should be considered. It is essential to ensure that the chosen equipment complies with relevant regulations and standards and can provide the required nitrogen purity and flow rate.

Holang Tech(Suzhou)Co.,Ltd is an innovative technology company specializing in industrial gas technology,providing a variety of gas treatment equipment including nitrogen generators,and provide global customized gas solutions to meet the specific needs of different applications.

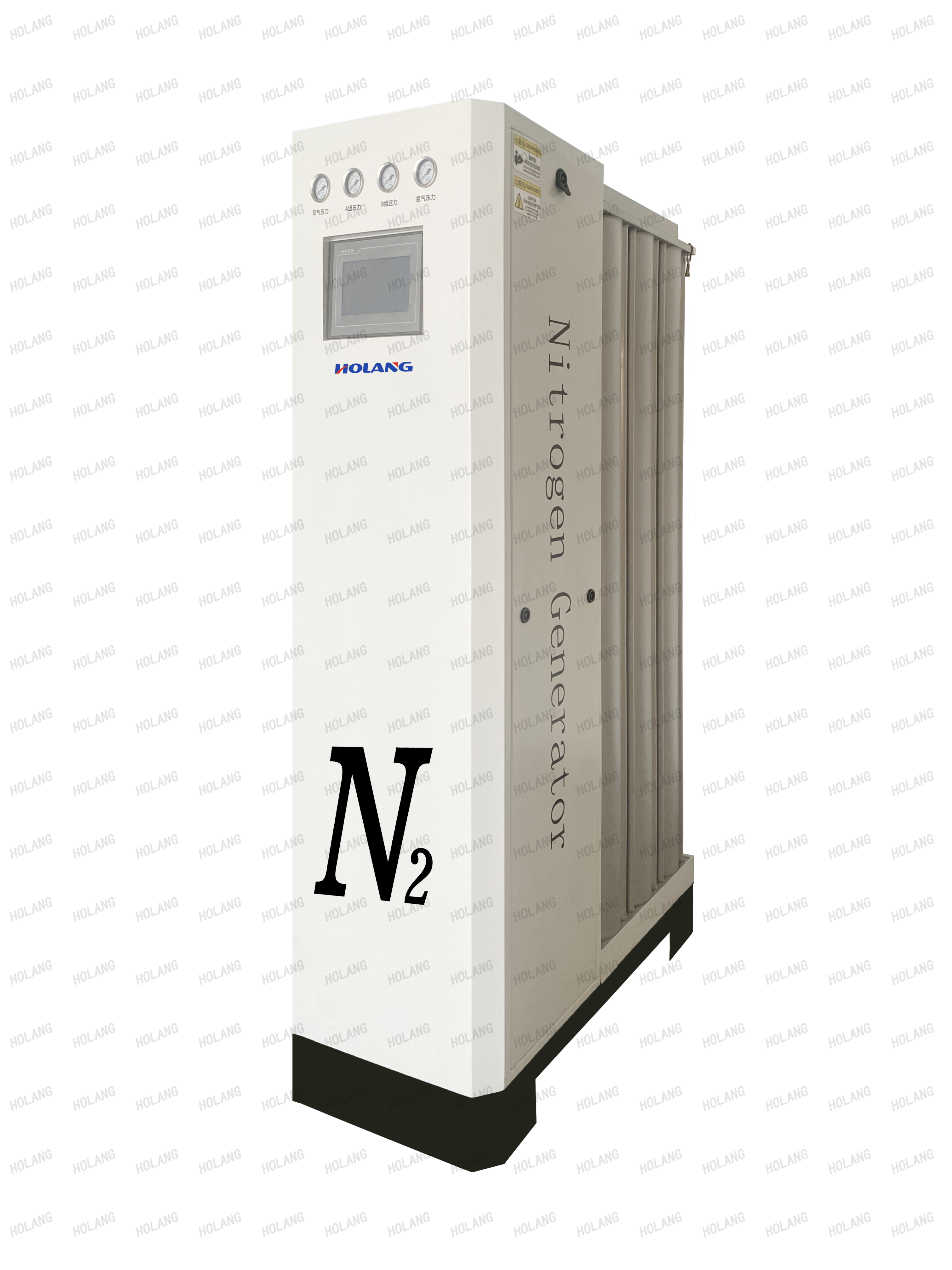

Advantages of HOLANG nitrogen generators include:

1.On-site nitrogen production, eliminating safety hazards associated with high-pressure gas cylinders or low-pressure liquid nitrogen tanks.

2.Nitrogen generators provide a continuous and efficient source of nitrogen, reducing costs associated with repetitive refills and transportation. They eliminate the need for external suppliers, thus lowering long-term operational expenses.

3.The equipment is equipped with an energy-saving mode that allows adjusting nitrogen purity and flow rate according to demand, resulting in energy consumption savings.

4.Modular design with a compact structure, occupying minimal space and facilitating installation.

5.Standard adsorption modules made of aerospace precision aluminum alloy, ensuring corrosion resistance and aesthetic appearance.

6.Expandable design allows for easy expansion of equipment according to requirements. Independent modules are easy to extract and replace without affecting overall performance, reducing maintenance and operation costs.

7.Touchscreen intelligent control panel with high automation and user-friendly operation.

8.Closed-loop monitoring of inlet and outlet pressure, flow rate, and purity, with built-in alarm functions for abnormal conditions. Mechanical safety valves are also installed to ensure safe usage.

9.Easy disassembly and connection technology facilitate troubleshooting and maintenance.

Overall, nitrogen generators are vital tools in the biopharmaceutical industry, providing a reliable and cost-effective source of high-purity nitrogen for various applications.